Mastering industrial printing: the most relevant trends in thermal transfer ribbons (TTR)

Master industrial printing: the most relevant trends in thermal transfer ribbons (TTR) for maximum performance

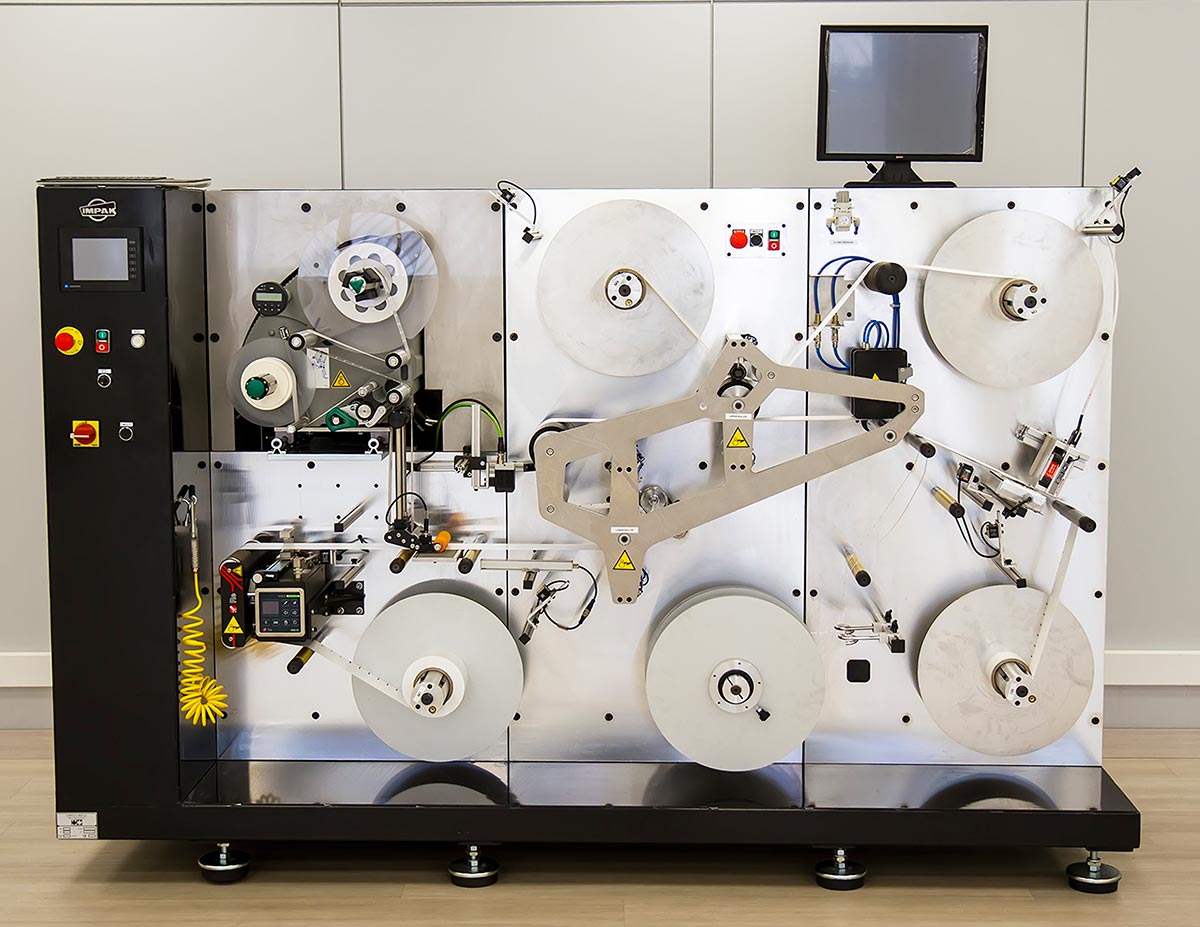

At the heart of product identification, traceability and inventory management in modern industry is a fundamental technology: thermal transfer printing. The essential component that drives this technology is thermal transfer ribbons, known in professional jargon as ribbon or TTR. If your business depends on accurate and durable labelling, understanding the latest trends in TTR ribbons is not an option, it is a strategic necessity to optimise your operations.

This article has been carefully crafted to inform you about the innovations that are transforming the use of ribbon and how selecting the right option can improve the efficiency and reliability of your labelling. Get ready to discover how the right ribbon can catapult your printing processes.

Key trends redefining thermal transfer ribbons (TTR)

The thermal transfer ribbon market is constantly evolving, driven by the need for greater efficiency, strength and sustainability in industrial and commercial labelling. We explore the trends that are setting the pace in the ribbon world:

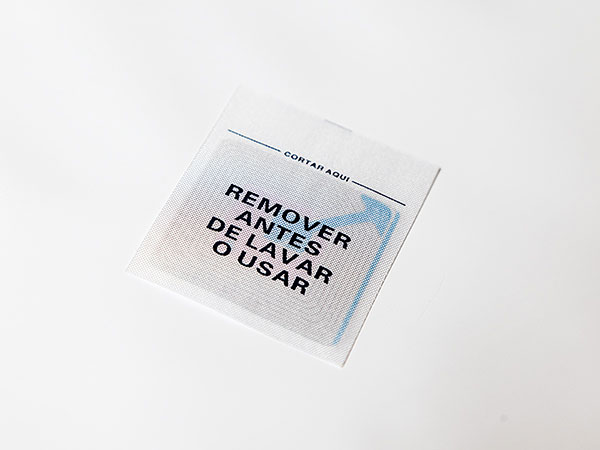

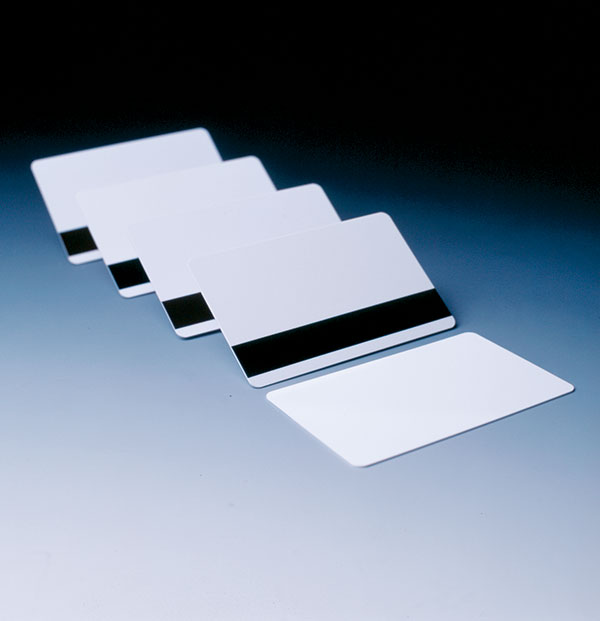

1. Multi-substrate ribbon versatility: printing quality on a variety of surfaces

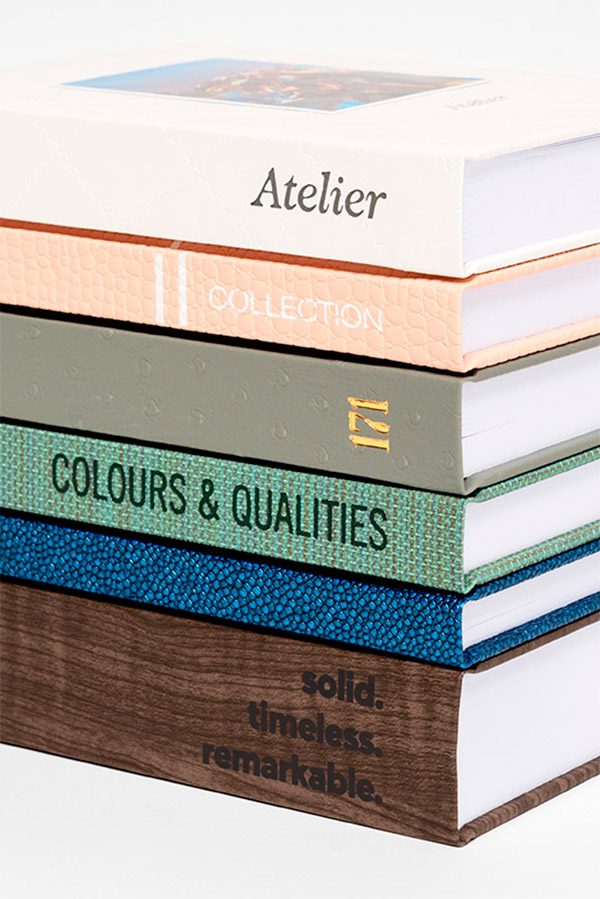

A key trend in transfer ribbon development is to create durable prints on a wide range of materials, from various plastics (PE, PP, PET, PVC) to textiles, rough materials or specially coated surfaces. This versatility is crucial for companies that label products with diverse packaging or that need to identify unconventional materials. Choosing the right Ribbon for each substrate is crucial to ensure the desired print quality and resistance.

-

Application examples: labelling of flexible packaging, textile identification, tyre labels, marking on uneven surfaces.

-

Key to Success: Ensure compatibility between TTR ribbon, label material and printer configuration.

2. TTR ribbons optimised for high speed: efficient printing while minimising production line downtime

Speed is synonymous with productivity in industrial printing. The latest innovations in TTR ribbons focus on enabling high quality printing at ever increasing speeds. A speed-optimised ribbon transfers efficiently with less thermal energy, which not only speeds up the labelling process on high-performance printers, but also reduces wear and tear on the printhead, extending its life and reducing maintenance costs.

-

Operational benefit: increases production line throughput, reduces downtime, optimises the use of thermal transfer printers.

-

Ideal for: distribution centres, high throughput production lines, logistics companies, food processing lines.

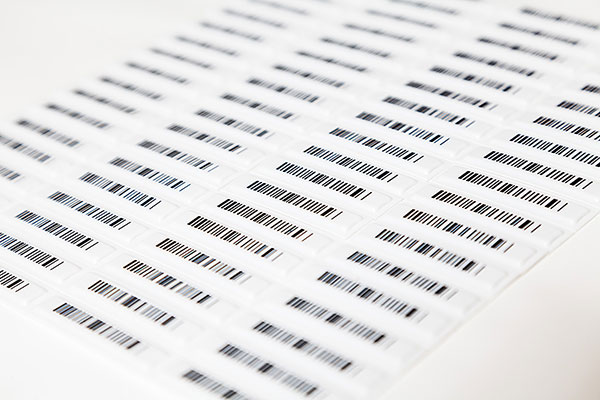

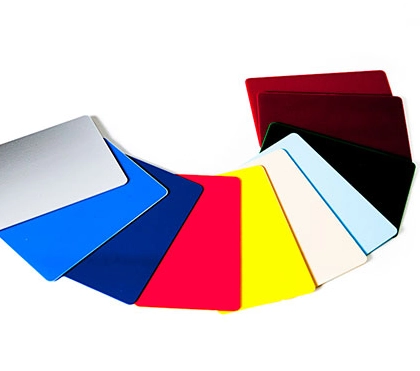

3. The rise of the ultra-strong resin ribbon: extreme durability for the highest demands

When it comes to heat transfer ribbons that must withstand the harshest environments, resin ribbon takes the lead. This trend responds to the growing need for labels that can withstand exposure to harsh chemicals, solvents, extreme temperatures, intense abrasion and adverse weather conditions. A high quality resin ribbon ensures that critical information (barcodes, batch numbers, warnings) remains legible and scannable throughout the supply chain and product life, even in the harshest conditions.

-

Key applications: automotive parts labelling, chemical identification labels, electronic tags, outdoor labels.

-

Operational benefit: reduces reading errors, minimises the need for re-labelling, ensures regulatory compliance.

TTRLand

4. Sustainable thermal transfer ribbons: Printing with an environmental conscience

Sustainability is no longer an option, it is a market requirement. The ribbon industry is responding by developing more environmentally friendly thermal transfer ribbons. This includes reducing the use of solvents in manufacturing, producing ribbons with thinner polyester base material, cones made from recycled materials, optimising packaging and ribbons that require less energy to print.

-

Characteristics: lower solvent content, recycled core materials, optimised packaging, lower printing temperature.

-

Impact: contributes to the company’s sustainability objectives, improves brand perception.

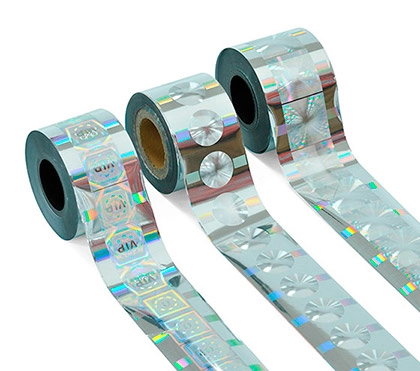

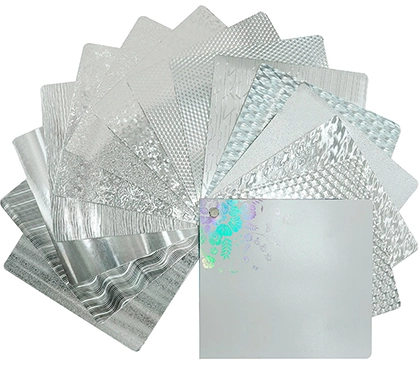

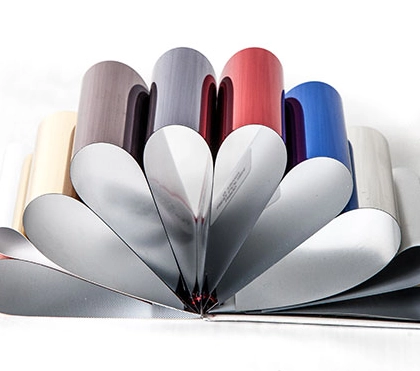

5. The rise of coloured and speciality ribbons: beyond black monochrome

While black ribbons are still the most common, the demand for coloured and speciality thermal transfer ribbons is growing. Colour printing makes it possible to include logos, design elements or highlight critical information directly on the label during the printing process. In addition, there are TTR ribbons with security features (UV inks, holographic elements) or specific formulations for indirect food contact or medical applications.

-

Examples: colour logos on logistics labels, safety marking, medical device labelling, nutritional information on packaging.

-

Benefit: enhances visual identity, adds layers of security, meets specific regulatory requirements.

Choosing the right ribbon: a strategic approach

Selecting the right heat transfer ribbon is a strategic decision that directly impacts the quality, durability and cost of your labels. Consider the following factors when choosing your ribbon:

-

Printer type: make sure the Ribbon is compatible with your thermal transfer printer model (flat head or near edge).

-

Label material: the Ribbon must adhere properly to the substrate (paper, synthetic, etc.).

-

Environmental conditions: What will the label be exposed to (temperature, humidity, chemicals, abrasion).

-

Print speed: the Ribbon must be suitable for the speed at which you print.

-

Regulatory requirements: Certain industries require thermal transfer ribbons to meet specific regulations (e.g. food contact, hazardous materials).

Consulting with an expert TTR ribbon supplier can provide you with the necessary elements for an optimal choice.

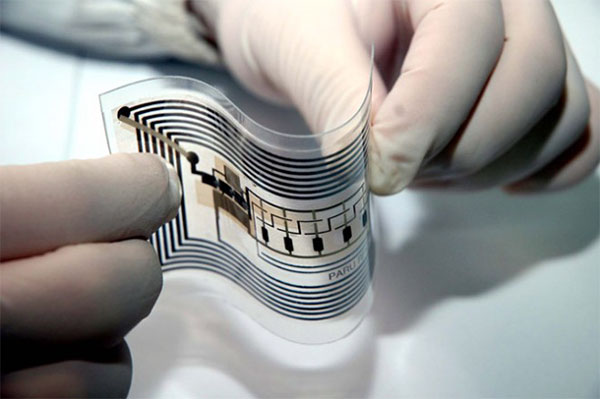

The future of TTR: more intelligence and connectivity

Looking to the future, we can expect thermal transfer ribbons to incorporate elements of “intelligence”. While the ink itself is passive, the information it prints is increasingly dynamic and connected (QR codes, serialised barcodes). We could see innovations in the packaging or the core of the Ribbon such as the incorporation of a chip to enable better inventory management or proactive end-of-roll notifications. The integration of thermal transfer ribbons with data management systems will become tighter and tighter, improving efficiency and traceability throughout the supply chain.

Investing strategically in your thermal transfer ribbons

Thermal transfer ribbons, or Ribbons as many know them, are a critical component of your identification and traceability strategy. Staying on top of TTR ribbon trends will allow you to optimise your labelling processes, reduce long-term costs, improve the durability and legibility of your information and ultimately strengthen the efficiency of your supply chain.

The right ribbon is a smart investment that ensures every printed label performs its function perfectly. From ultra-durable thermal transfer ribbons to sustainable, specialised solutions, the market offers a range of possibilities to suit your most demanding needs. Don’t underestimate the power of choosing the right Ribbon to power your operations and ensure the reliability of your labelling – take advantage of TTR ribbon trends to take your printing to the next level!